Introduction:

In today's highly competitive business landscape, maintaining consistent quality and ensuring customer satisfaction are paramount to the success and longevity of any organization. These two aspects go hand in hand and form the foundation for building a loyal customer base and fostering long-term relationships with clients.There are hundreds of way to address this. Few of them are summarized below:

100 ways :

Here are 100 ways to avoid process and product failure on the shop floor to maintain consistent quality and customer satisfaction:

1. Implement rigorous quality control measures

2. Conduct regular audits of production processes

3. Train employees on quality standards and best practices

4. Use effective inspection tools and techniques

5. Implement a robust supplier quality management system

6. Conduct thorough supplier audits

7. Establish clear quality requirements for suppliers

8. Monitor and address quality issues with suppliers promptly

9. Conduct regular maintenance of equipment and machinery

10. Implement preventive maintenance schedules

11. Ensure proper calibration of measuring instruments

12. Implement a comprehensive training program for operators

13. Provide ongoing training and skill enhancement programs for employees

14. Set clear quality goals and targets

15. Monitor key performance indicators (KPIs) regularly

16. Implement statistical process control techniques

17. Conduct root cause analysis for quality issues

18. Implement corrective and preventive action plans

19. Communicate quality goals and targets to employees

20. Foster a culture of continuous improvement

21. Encourage employee feedback on quality improvements

22. Implement a robust document control system

23. Regularly review and update standard operating procedures (SOPs)

24. Implement a robust change management process

25. Conduct regular process risk assessments

26. Implement controls to prevent non-conforming materials from entering the production line

27. Conduct regular material inspections and testing

28. Implement a robust product traceability system

29. Implement effective stock management practices

30. Conduct regular inventory audits

31. Implement proper handling and storage practices for materials

32. Establish clear protocols for handling customer complaints

33. Document and investigate customer complaints promptly

34. Take prompt corrective actions to address customer complaints

35. Conduct regular customer satisfaction surveys

36. Analyze customer feedback to identify areas for improvement

37. Monitor customer satisfaction trends and take corrective actions as needed

38. Implement effective change control procedures

39. Conduct thorough impact assessments for process changes

40. Involve relevant stakeholders in change management processes

41. Conduct regular safety inspections on the shop floor

42. Implement effective safety training programs for employees

43. Ensure adherence to safety protocols and procedures

44. Conduct regular safety drills and exercises

45. Establish a robust waste management system

46. Implement recycling and reusing initiatives

47. Monitor energy consumption and implement energy-saving measures

48. Implement effective environmental management practices

49. Conduct regular environmental audits

50. Establish clear guidelines for workplace organization and cleanliness

51. Implement 5S practices (Sort, Set in Order, Shine, Standardize, Sustain)

52. Implement visual management tools and techniques

53. Establish clear guidelines for equipment layout and positioning

54. Implement error-proofing techniques, such as poka-yoke

55. Conduct regular equipment performance evaluations

56. Implement effective changeover procedures

57. Conduct regular throughput analysis to optimize production flow

58. Implement effective production scheduling techniques

59. Monitor on-time delivery performance

60. Implement effective order tracking systems

61. Implement effective process control systems

62. Conduct regular process capability studies

63. Implement error detection and prevention systems

64. Establish clear quality gates at critical process stages

65. Conduct regular supplier performance evaluations

66. Establish clear communication channels with suppliers

67. Implement effective risk management practices

68. Conduct regular industry benchmarking studies

69. Implement effective cost control measures

70. Conduct regular cost of quality analysis

71. Implement effective product lifecycle management practices

72. Conduct regular product performance evaluations

73. Implement effective serialization and labeling practices

74. Conduct regular equipment validation and qualification studies

75. Implement effective inventory control systems

76. Monitor and control product shelf life

77. Implement effective root cause analysis techniques

78. Establish a continuous improvement feedback loop with customers

79. Conduct regular production process simulations and testing

80. Implement effective capacity planning and resource allocation techniques

81. Monitor and control variation in production processes

82. Implement effective employee performance evaluation systems

83. Conduct regular leadership and management training programs

84. Establish clear communication channels between management and shop floor employees

85. Implement effective employee engagement initiatives

86. Conduct regular employee satisfaction surveys

87. Implement effective supplier performance evaluation systems

88. Establish clear supplier communication channels

89. Conduct regular supplier collaboration and improvement meetings

90. Implement effective project management practices for process improvement initiatives

91. Establish clear goals and objectives for process improvement initiatives

92. Monitor and control project timelines and budgets

93. Conduct regular project status reviews and updates

94. Implement effective change communication and training programs

95. Conduct regular employee recognition and reward programs

96. Implement effective data collection and analysis techniques

97. Establish clear key success factors for process improvement initiatives

98. Monitor and control progress towards project goals

99. Implement effective data visualization and reporting techniques

100.

Celebrate and communicate successes achieved through process improvement initiatives

Remember, this is just a starting point, and you can customize and prioritize these strategies based on the specific needs and requirements of your organization.

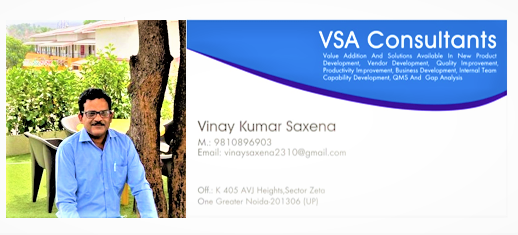

Written by:

Very well compiled all methodology of customer satisfaction and manufacturing quality improvement. Most important points to improve customer satisfaction are maintaining and improving product quality, ontime delivery and

accepting and improving upon customer feedback

Thank you

Ashwani Pandey

Great very well consolidated and covered every aspect of Quality

An article which has covered every aspect of delivering a quality and reliable product or service which helps in building customer relationship...Quality should act as a part of profit centre...All the best..👍

GREAT 👍

Great